Our Strengths

Since 1967, Kyoto has been growing steadily by developing technology for printed wiring board development using screen printing technology that has been cultivated in the traditional design of kimono called Kyoto Yuzen.

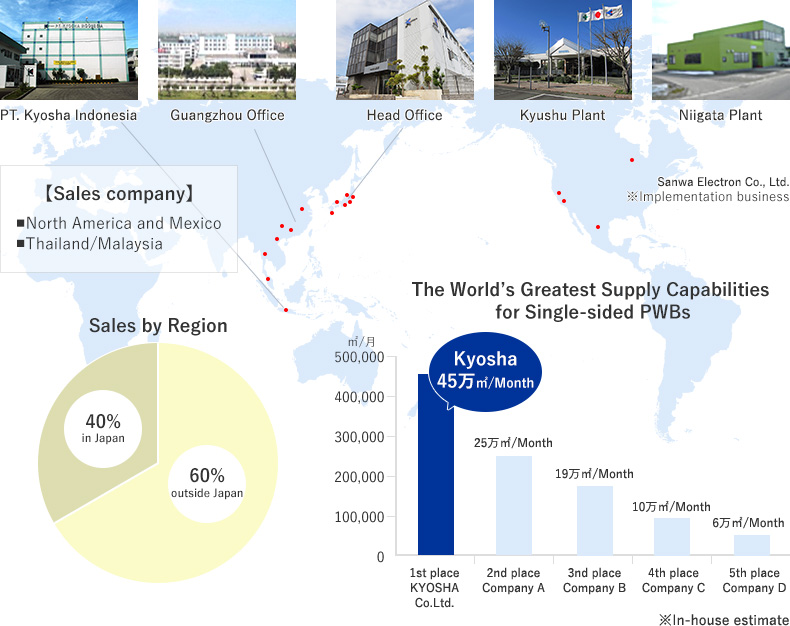

Strength 1: Our global supply system

Starting in 1993, Kyosha took the lead ahead of other companies to become the first to establish a global production and sales system, and we have been supplying products worldwide ever since. We are particularly proud to have the world’s best supply capacity for our key product, single-sided PWBs.

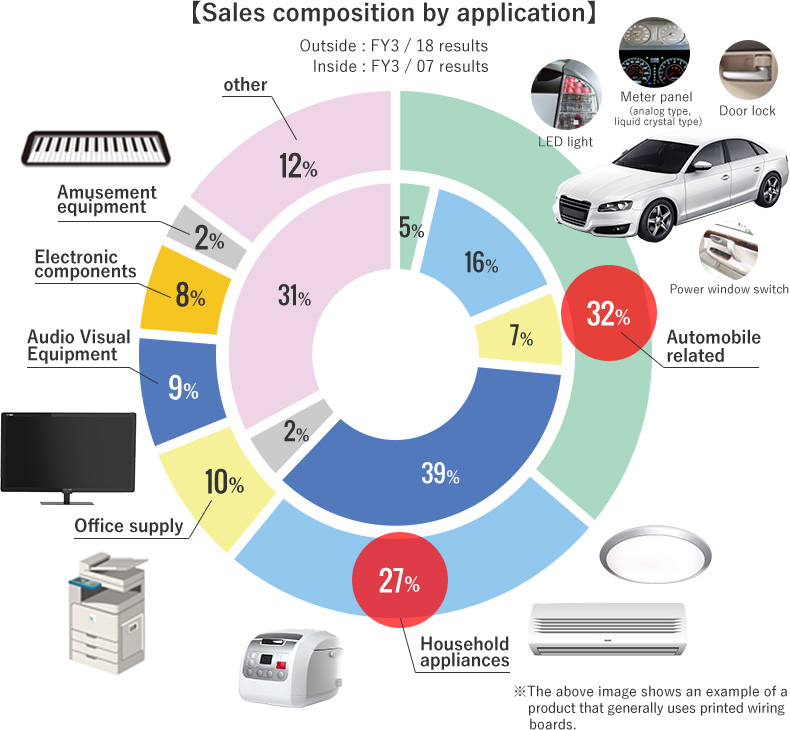

Strength 2: Our expansion into a broad range of product categories

Our expansion into a broad range of product categories is one of our strengths. In line with changes in the external environment, we are systematically assessing product categories and shifting gears the new market to broaden our business achievements. Currently, we are putting our efforts into the supply of automotive products and the supply of eco-conscious consumer electronics, which are both growing fields.

Strength 3: Development technology for printed wiring boards

Taking advantage of the printing technology that we have cultivated, we have been developing new products that always meet the needs of our customers. From now and into the future, we will move forward with environment-friendly products and enhancing new markets in other potential fields.